"OPERATIONAL DEPARTMENTS"

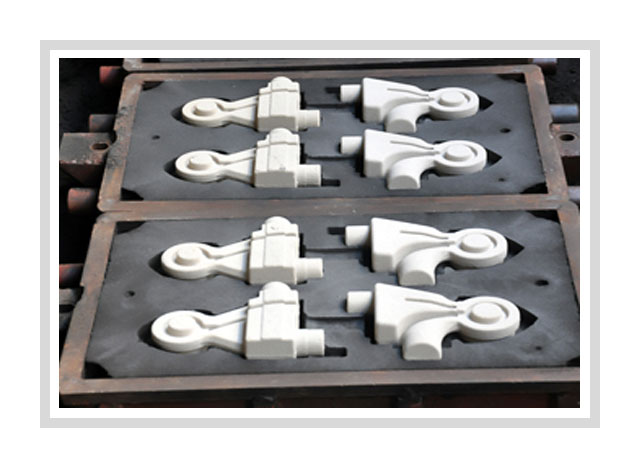

1.MOULDING DEPARTMENT:

• 300 SIZE PNEUMATIC PRESS – 2 PAIR

• 200 SIZE JOLTER SQUEEZE PRESS – 6 PAIR

• 100 SIZE HAND PRESS – 7 PAIR

2. MOULDING BOX:

• 20*21 – 550 UNITS

• 17*21 – 350 UNITS

• 14*21 – 550 UNITS

• 28*30 – 400 UNITS

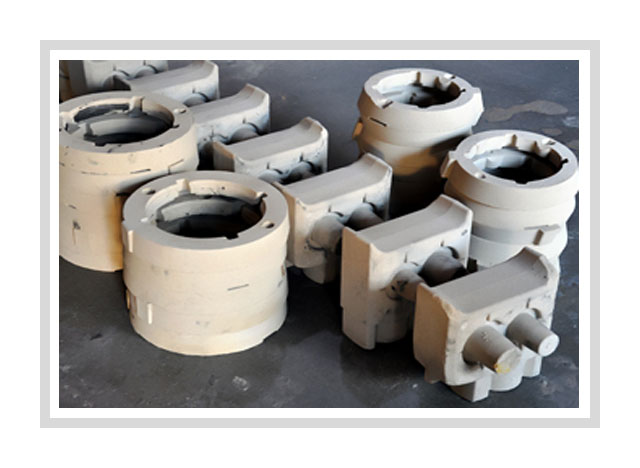

3. CORE DEPARTMENT:

• 5 KG CAPACITY CORE MACHINE – 3 UNITS

• 10 KG CAPACITY CORE MACHINE – 1 UNIT

• SHOT BLASTING MACHINE – 500 KG PER CYCLE (1 UNIT)

4. GRINDING, FETTLING & PAINTING DEPARTMENT:

• OPERATIONAL CAPACITY – 18 TONNES PER DAY

5. TESTING FACILITY:

• C.E METER: FOR TESTING CARBON & SILICON CONTENT OF THE MOLTEN METAL

• SPECTROMETER: ARL (SWISS) MAKE WITH 26 ELEMENTS ANALYZING CAPACITY.

• IMAGE ANALYSER: WITH CAMERA ATTACHED TO THE MICROSCOPE.

• SAND TESTING: ALL THE NECESSARY SAND TESTING EQUIPMENTS FOR BOTH GREEN SAND MOLDING & SHELL MOLDING PROCESS

• WET LAB: FULL FLEDGED WET LAB FOR CHEMICAL ANALYSIS.

• UTM: 40 TONS CAPACITY UNIVERSAL TESTING MACHINE FOR TENSILE STRENGTH, YIELD STRENGTH AND ELONGATION.

• HARDNESS TESTER: 3000 KGS BRINELL HARDNESS TESTING MACHINE.

• IMPACT TESTING MACHINE

• RADIOGRAPHY: IN COLLABORATION WITH NABL ACCREDITED LABORATORY (AS PER CLIENT’S REQUIREMENTS)

6. MACHINING FACILITY:

• CNC MACHINE (ACE MICROMATIC):

1) 1 UNIT – SUPER JOBBER XL 200

2) 1 UNIT – SUPER JOBBER XL 300

• LATHE MACHINE: 4 UNITS

• RADIAL DRILL: 1 UNIT

• PILLAR DRILL: 4 UNIT

• TAPING DRILL: 1 UNIT

• GAUGES: ALL NECESSARY CATEGORIES OF GUAGES DEPENDING UPON THE TOLERANCES OF RESPECTIVE DRAWING